| Symposium |

|

|

|

|

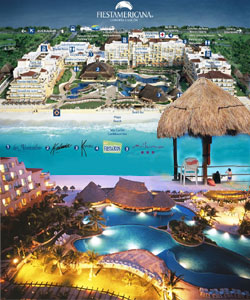

| Venue |

|

|

|

|

|

| Information |

|

|

|

|

|

|

|

|

| Sponsorship |

|

|

|

| Submission |

|

|

|

| Program |

|

|

|

|

|

| Registration |

|

|

|

| Instructions |

|

|

|

| Post Symposium |

|

|

|

| Previous Events |

|

|

|

| Contacts |

|

|

|

|

BIOGRAPHY

Applications of Research Derek Fray is the inventor on approximately 179 patents arising from 62 families of patents and the following are being commercialised at the present time. The numbers give the number of the patent on the list.

Measurement of Hydrogen in Solid Steel [2]

This is a method for the detection of hydrogen emanating from a steel surface. The hydrogen is swept away by a known flow rate of air and the hydrogen content measured by a fuel cell. The rate of hydrogen can be related to the concentration of hydrogen in the bulk material. As hydrogen is a by-product of corrosion, this method is able to detect corrosion inside pipes and many units have been sold to the oil and gas industry as a corrosion detector. This method was developed under a DTI award and Ion Science Ltd who is selling this device owns the patent.

Measurement of Hydrogen in Molten Aluminium [16]

Hydrogen is a major cause of porosity in aluminium alloys and needs to be measured, prior to casting. This is achieved by measuring the hydrogen concentration in the molten aluminium with a novel solid electrolyte sensor, based upon a proton conducting solid electrolyte. This device has been licensed by the University of Cambridge to Environmental Monitoring and Control Ltd who are selling the device. This company is financed by private equity.

Measurement of Gaseous Species at High Temperature [21,25,27]

There is a need for in-situ measurement of polluting gas species at high temperatures. Various sensors using solid electrolytes have been developed and are now being commercialised by Environmental Monitoring and Control Ltd.

Addition of Sodium to Molten Aluminium Alloys [20]

Sodium is added to molten aluminium silicon alloys to modify the structure of the solidified alloy and, thereby, increase the mechanical properties. The straight addition of sodium causes considerable pollution as the added sodium floats to the surface and oxidises. A method of electrolysing NaOH inside a sodium conducting electrolyte (sodium beta alumina) has been developed which allows the controlled addition of sodium, beneath the surface of the melt. Another advantage of the process is that NaOH is safer to handle than sodium metal and is considerably cheaper. Foseco Ltd. are commercialising this unit.

Addition of oxygen to wounds to increase the rate of healing [6]

It is well known that oxygen can increase the rate of healing of wounds. The use of oxygen cylinders to supply oxygen is cumbersome so a small oxygen generator has been developed which takes air and converts it into pure humidified oxygen which can then flow to the wound. The University of Cambridge has licensed this device to Inotech AMD Ltd who are carrying out human trials. The University of Cambridge Challenge Fund and Venture Capitalists are investing in this company.

Tin-filled carbon nanotubes as anodes in Lithium-ion batteries [5,8]

The capacity of existing graphite anodes in lithium-ion batteries is relatively low. Tin and other metals have a high capacity for lithium but the alloys undergo a very large volume change on the insertion and de-insertion of lithium causing decrepitation. One possible way of overcoming this problem is to encapsulate the tin in carbon nanotubes. An electrochemical method of achieving this has been developed in which graphite rods, in the presence of tin chloride, are converted into tin filled carbon nanotubes. A battery company in the UK and Government Laboratory in Canada has recently evaluated these. The results show that the capacity of these tin anodes is higher and last for more cycles than the results, reported by others, in the literature. Negotiations are about to start with battery companies regarding the exploitation of these anodes.

Magnetocaloric Alloys

These are alloys that either heat up or cool down when subjected to a magnetic field . This effect can be used to build a solid-state refrigerator and Camfridge Ltd is undertaking this opportunity. The University of Cambridge Challenge Fund and Venture Capitalists are supporting the company.

Microwave Enhancement of the Segregation Roast [13]

This is a method of treating sulphide ores by treating the ores in a microwave oven with carbon and a source of chlorine which could be PVC, ammonium chloride or hydrochloric acid. After reacting, the metal sulphide is reduced to metal and the sulphur collected. Belle Watkins Mines Inc is commercialising this idea.

Electro-deoxidation of metal oxides [1,2,3,4,7,9,10,12,14,15,17,22]

Electro-deoxidation is a method whereby a metal oxide is made the cathode in a bath of a salt of a very electropositive element (CaCl2). On the application of sufficient voltage, the oxygen in the oxide ionises rather than the deposition of the cation in the melt. This approach can be applied to most metal oxides that are less stable than calcium oxide. A large number of metal oxides have been successfully reduced. If two or more oxides are mixed together and reduced, the product is an alloy rather than a mixture of the pure metals. Similarly, intermetallic compounds can be produced by this technique avoiding the very high temperatures that are usually used. In conjunction with an inert anode, the products are metals or alloys and oxygen. This approach is also of considerable interest to NASA and ESA as the ability to produce oxygen on the moon is of considerable interest. The above patents have been licensed to Metalysis Ltd who has raised about L20m to commercialise the process.

|

|

|